Fluted PP sheet boxes (also known as PP corrugated sheet boxes) are lightweight, durable, and reusable. Because of these benefits, they have become a preferred choice for packaging in logistics, warehousing, and supply chains. In this guide, we show the full production workflow step by step.

- Preparing Raw Materials

First, the process begins with polypropylene (PP) granules. Workers mix them with additives such as color masterbatch, anti-static agents, UV stabilizers, and flame retardants. This preparation ensures that the sheet performs well in demanding environments.

- Extrusion of PP Corrugated Sheets

Next, the blended PP melts and passes through a flat die mold. The machine forms a hollow corrugated structure.

Thickness: 2–12 mm

Width: up to 2,100 mm

Finish: smooth, laminated, or embossed

Then, cooling, vacuum forming, and traction stabilize the sheet. As a result, the panels remain uniform in thickness and density. - Cutting, Creasing & Folding (One Machine)

After extrusion, large corrugated sheets move to an automatic cutting and folding machine. This step combines:

Cutting panels to size

Creasing fold lines for accuracy

Folding panels into box shapes

Therefore, manufacturers save time and keep the dimensions consistent.

- Ultrasonic Spot Welding

Then, technicians reinforce panels with ultrasonic spot welding. They add welding spots along fold lines, corners, and load points. This action strengthens the structure and prevents collapse under pressure.

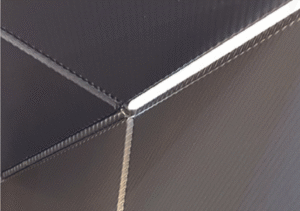

- Automatic Edge Welding

Next, the edge welding machine seals seams. It welds continuously along edges and bottom joints. This process increases rigidity, creates neat finishes, and extends the lifespan of the box.

- Extra Reinforcement

For heavy-duty packaging, companies add aluminum profiles, rivets, or hot-melt tape. Moreover, these reinforcements improve impact resistance and stacking strength.

- Accessory Installation

Then, accessories are fitted according to client needs. Examples include lids, handles, Velcro straps, label holders, wheels, and stacking corners. In addition, these options make the box more versatile across industries.

- Final Inspection of Fluted PP Sheet Boxes

Finally, inspectors check each box for size, squareness, and corner strength. They also test stacking load capacity. Foldable boxes are packed flat, while fixed boxes are stacked on pallets for delivery.

Binding Solutions for PP Turnover Boxes

Ultrasonic Welding/Binding

- No extra consumables, eco-friendly

- Strong bonding, prevents cracking

- Fast process, ideal for mass production

- Smooth and neat joint appearance

Flat Wire Binding

- Low cost and simple process

- Detachable/reusable, high flexibility

- Suitable for medium-duty packaging

- Easy to operate and maintain

Seamless Heat-Press Bonding

- Clean appearance without visible marks

- Good sealing performance, waterproof and dustproof

- Enhances overall structural strength

- Perfect for packaging requiring durability and aesthetics

Rivet Binding

- Excellent load-bearing capacity, ideal for heavy-duty boxes

- Strong impact and tensile resistance

- Long service life, stable structure

- Can be reinforced with metal or plastic fittings